How do we promise you good quality pumps?

You might think there are a bunch of beauty pump providers out there; why should I choose Shero's pumps. Today, We are going to tell you the benefits of choosing us as your beauty pump provider!

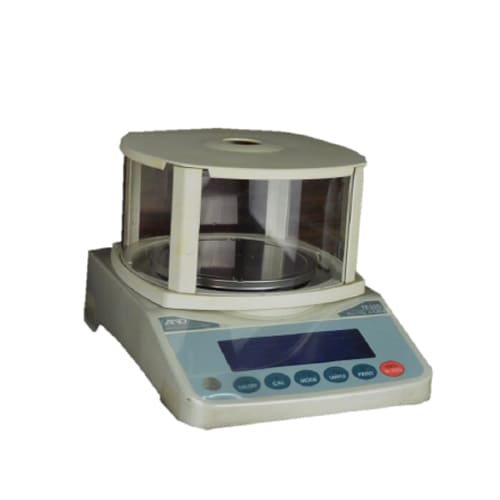

All the pumps we provide have been through strict Quality Control. Our Quality Control department has a special system for testing the pumps and see if they reach the standard. If there is one under the standard, our Quality Control department members abandon it right away. This is why Shero can always provide high-quality pumps. Want to know all the flow and standards about our beauty pump Quality Control steps? All the answer is going to be revealed below.

All the pumps we provide have been through strict Quality Control. Our Quality Control department has a special system for testing the pumps and see if they reach the standard. If there is one under the standard, our Quality Control department members abandon it right away. This is why Shero can always provide high-quality pumps. Want to know all the flow and standards about our beauty pump Quality Control steps? All the answer is going to be revealed below.